Autoclave Sterilization

This is the most commonly used sterilization method in hospitals. Autoclaves are classified into gravity displacement sterilizers and pre-vacuum sterilizers.

Gravity displacement sterilizers consist of a high-pressure boiler with double walls. Steam enters the sterilization chamber, accumulates, and raises the pressure, which in turn increases the temperature. Once the steam reaches a specific temperature and is maintained for a set amount of time, all microorganisms can be eradicated.

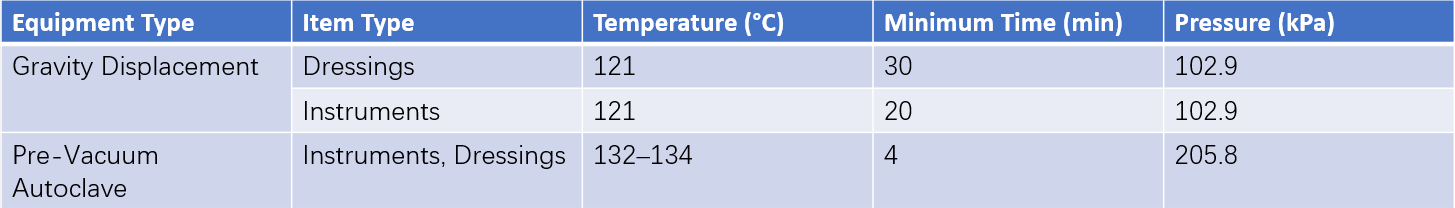

Table 1 Sterilization parameters for steam autoclaves

Many hospitals now use more advanced pre-vacuum sterilizers. These devices first evacuate air from the sterilization chamber to create a vacuum, and then steam is directly introduced into the chamber via a central steam supply system. This ensures an even distribution of steam within the sterilization chamber, reduces the overall sterilization time, and minimizes damage to the sterilized items.

Autoclave sterilization is suitable for most medical items, including surgical instruments, gowns, and fabric-based dressings. Ensuring the effectiveness of autoclave sterilization requires adherence to strict procedures:

- The maximum volume of a sterilization package should be 40 cm (length) × 30 cm (width) × 30 cm (height).

- The package should not be overly tight and should not use ties.

- Items in the sterilization chamber should not be packed too densely.

- Special internal and external sterilization indicator tapes should be placed in the packages. When both pressure and temperature meet sterilization standards, the internal tape turns black from colorless, and the external tape shows black stripes.

- Sterilized items must be labeled with an expiration date, which is generally set at two weeks.

Chemical Gas Sterilization

This method is used for sterilizing medical materials that are sensitive to high temperatures or moist heat, such as electronic instruments, optical instruments, endoscopes and their specialized instruments, catheters, drainage tubes, and other rubber-based items. Common chemical gas sterilization methods include ethylene oxide gas sterilization, hydrogen peroxide plasma sterilization, and formaldehyde vapor sterilization.

Ethylene Oxide Gas Sterilization

For this method, the effective gas concentration ranges from 450 to 1,200 mg/L, and the sterilization chamber temperature is maintained between 37°C and 63°C. The sterilization process typically takes 1 to 6 hours. The validity period of sterilization is six months. Residual ethylene oxide gas from this process cannot be naturally dissipated and must instead be vented through a specialized exhaust system.

Hydrogen Peroxide Plasma Sterilization

The principle of this method involves generating glow discharge in the sterilization equipment, using hydrogen peroxide as the medium to produce low-temperature plasma for effective sterilization. The hydrogen peroxide concentration is greater than 6 mg/L, the temperature ranges from 45°C to 65°C, and the process takes between 28 and 75 minutes. Items must be thoroughly dried before sterilization.

Boiling Method

This method is suitable for metal instruments, glass products, and rubber items. Boiling water at 100°C for 15 to 20 minutes can kill general bacteria, but bacterial spores require boiling for at least one hour. This method is simple, effective, and suitable for use in primary healthcare facilities or emergency situations. To save time and improve sterilization quality in high-altitude regions, a pressure cooker may be used for boiling sterilization, as its steam pressure can reach 127.5 kPa, and the internal temperature can rise to approximately 124°C, achieving sterilization in just 10 minutes.

Chemical Immersion Method

Chemical immersion can also be used to disinfect sharp surgical instruments, endoscopes, and other medical devices. A 2% neutral glutaraldehyde solution is commonly used for clinical disinfection, achieving a disinfecting effect in 30 minutes and sterilization in 10 hours. Other solutions used for disinfection include 10% formaldehyde, 70% alcohol, 1:1,000 benzalkonium bromide, and 1:1,000 chlorhexidine solutions.

Dry Heat Sterilization

This method is suitable for sterilizing heat-resistant and moisture-sensitive items, as well as materials through which steam and gas cannot penetrate, such as glass, powders, and oils. The sterilization process requires a temperature of 160°C for at least 2 hours, 170°C for 1 hour, or 180°C for 30 minutes.

Ionizing Radiation Sterilization

This industrial sterilization method is primarily applied to sterile medical consumables (such as disposable syringes and sutures) and certain pharmaceuticals. It commonly uses gamma rays emitted by cobalt-60 (60Co) or electron beams generated by accelerators as sterilizing agents.